Keystone XL Pipeline Fights Faux Environmentalist Energy Starvation

The US State Department has issued a final environmental impact statement, finding no significant environmental impacts from the pipeline. The bureaucratic process for approval of the pipeline is far from exhausted, however. The Obama agenda of energy starvation has barely begun to sink its fangs into Canada's oilsands, US coal, US offshore oil, US kerogens, US nuclear etc. -- despite the risk to the US economy of shutting down virtually all reliable forms of energy.

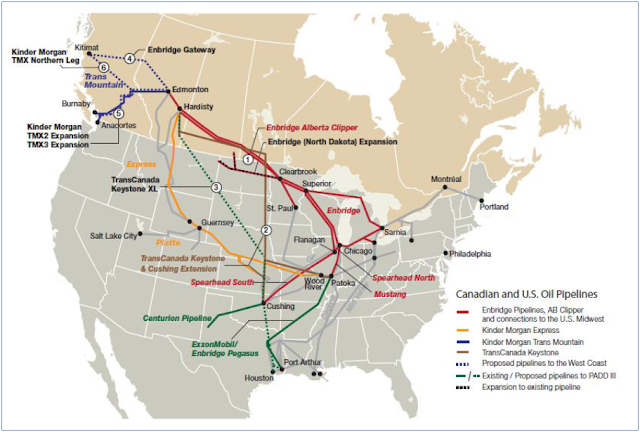

As for the Keystone XL and other oilsands pipelines -- Most analysts believe that it is the price differential (about $25) between North American oil prices and global oil prices which is driving various pipeline routes to the sea.

Will the pipeline connection to the Gulf Coast simply be a conduit for Canadian oil to be trans-shipped to foreign markets and capture more favorable world pricing? If so, how does that help America?

Or will the flow of 500,000 to 900,000 barrels a day through the Keystone XL pipeline to the Gulf Coast be sufficient to bring down bulging inventories of stranded, land-locked oil in Cushing, Oklahoma and eliminate, or at least substantially reduce the huge price spread between Brent and West Texas Intermediate?

If it doesn’t, and the over $25-per-barrel spread between U.S. domestic oil prices and world oil prices persists, new pipelines will be built in Canada to provide a more direct connection to global oil markets.

One way or another, it is oil price differentials, not James Hansen’s concerns, which will ultimately determine the flow and direction of oil from Canada’s tar sands. _Globe&Mail

Faux environmentalism is little more than a primal desire to return to a pre-industrial global state. Since such a return would inevitably result in the dieoff of several billion human beings, faux environmentalism is a thinly veiled yearning for a massive reduction of the human population to less than 10% of current levels.

Energy starvation of the developed world is the quickest route to this dieoff. By shifting from reliable forms of energy such as nuclear, coal, gas, etc. in favour of unreliable forms of energy such as big solar and big wind, faux environmentalism is apparently trying to bring about massive poverty, hunger, hardship, disease, and death. Think of that the next time you are solicited by Greenpeace, the Sierra Club, or World Wildlife Fund.

Labels: Canada, doombama, faux environmentalism, oil sands